Forklift Attachment Rotators

Rotators

Rotators add 360° revolving motion, in both directions, to truck forks. Used in food processing and manufacturing for inverting and dumping loads.

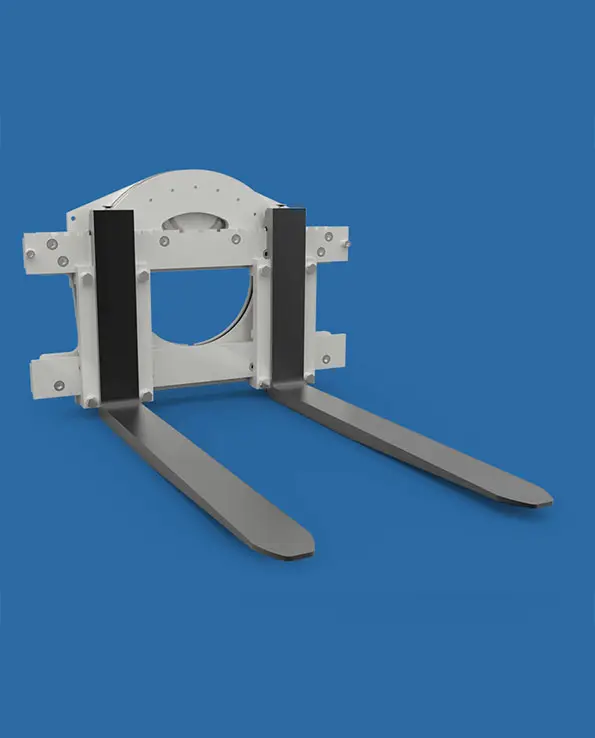

G-Series Rotator

G-Series Rotators give your driver the ability to quickly dump or invert a load, and then immediately return the forks to the pick-up position in one continuous motion. Cascade rotators are widely used in food processing, automotive manufacturing, chemical processing, recycling operations, smelting, and casting operations, and general manufacturing — anywhere it is necessary.

Features:

- Rugged Construction- Cascade’s gear drive box and ring gear design are proven to provide superior durability.

- Large visibility window gives the driver an excellent view of the fork tips. Center seal locks out contamination.

- Rotational Torque — Good torque specifications ensure smooth, positive rotation of the load.

- Many fork bar widths are available to suit a wide variety of applications.

- Rotators may be ordered with forks or with fork bars only.

Options:

- 180° Rotation Stop Group — Used when stopping rotation at precisely 180° is desirable.

- Special fork sizes and configurations

- Quick-Change Lower Mounting Hooks — Allow the rotator to be removed or installed in a matter of minutes without tools. (Quick-change hydraulic couplers available separately)

- Hydraulic Bin Retainer — Custom designed to clamp on top of bin to hold bin in place while rotating. Typically used when bin does not have fork pockets.

- Mechanic Bin Retainer — designed to retain lightweight bins.

- Side Stabilizers — to help retain the load during rotation.

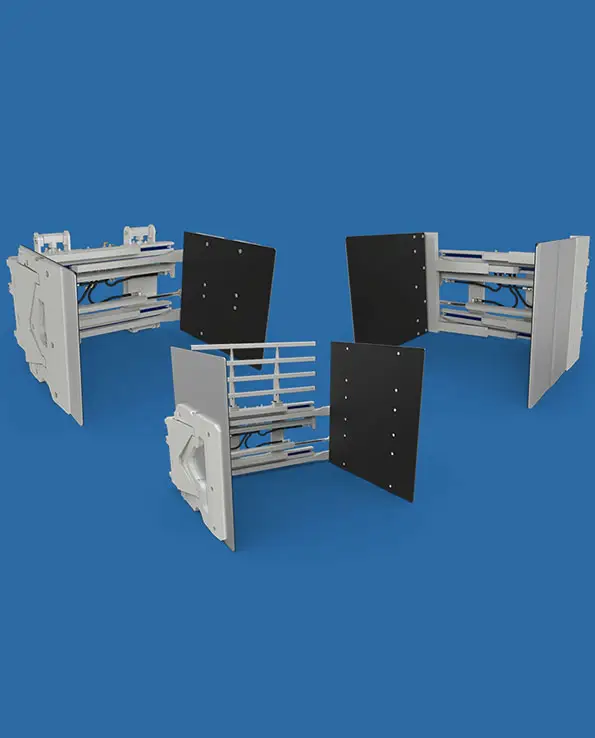

Other Rotators offered:

- 20G Agricultural Rotator

- Hydraulic Bin Rotator

- Bin Retainer

Additional information

| Capacity: | 4,500lbs. |

|---|---|

| Overall Width: | 33.9" – 42.3" |

| Fork Length: | 30" – 48" |

| Rotation: | 360° |

Similar Equipment

Related products

-

Push-Pulls Forklift Attachment

[woosw id="19174"]Allows you to ship, receive, and warehouse unit loads on inexpensive slip sheets rather than pallets. Products typically handled with a push/pull include bagged products such as seed, agricultural products and cement. Cased food, electronics, cosmetics, and bottled beverages are other examples of products packaged in this way. Contact an Atlantic Coast ToyotaLift representative to receive more information about your specific needs.

Models Available:

35E and 45E: 3,500 – 4,500 pounds

Rugged, heavy duty for high cycle slip-sheeted applications.

Mark 55: 3,500 – 4,500 pounds

Handle both slip sheeted and palletized product with this one attachment.

Quick Fork Mount: 3,500 – 4,500 pounds

Easy to remove for intermittent use.

Sheet-Sav: 3,500 – 4,500 pounds

Chamfered platen corners and gripper jaw design protects the slipsheet.

-

Fork Positioner L Series

[woosw id="19163"]Fork positioners allow lift truck operators to move the forks quickly and accurately to fit different pallet sizes without leaving their seats.

Features:

- Increase Productivity

by moving the forks without getting off the truck seat and accurately placing the load without additional truck maneuvering. - Reduce Damage

to pallets and products by ensuring the forks are in the ideal position for the load being handled. - Quick and Easy Installation

is achieved without welding and the use of a Sequence Valve or RFHC (Radio Frequency Hydraulic Control) permits the use of a single auxiliary valve to control an additional function.

Options:

- Many Fork Mounting Options

are available to match your application. Hook-on style forks, bolt-on forks, weighing forks (Weigh Forks) or Telescopic Forks are all compatible with many Fork Positioners. - Heavy Duty Load Backrests

are available for all Fork Positioners to help stabilize your load. - Various Opening Ranges

to suit most any application are available from narrow aisle, zero closing units to extra wide opening units extending far beyond the width of the truck.

- Increase Productivity

-

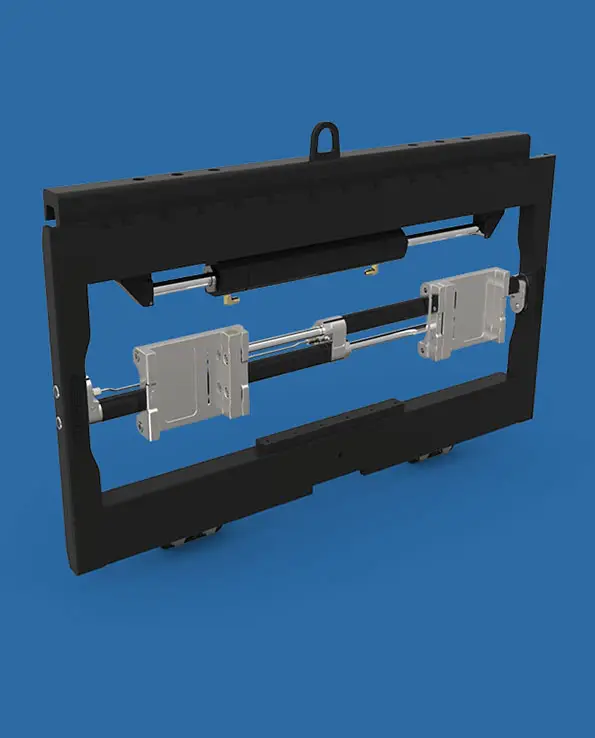

Fork Positioner K Series

[woosw id="19162"]Fork positioners allow lift truck operators to move the forks quickly and accurately to fit different pallet sizes without leaving their seats.

Features:

- Increase Productivity

by moving the forks without getting off the truck seat and accurately placing the load without additional truck maneuvering. - Reduce Damage

to pallets and products by e=nsuring the forks are in the ideal position for the load being handled. - Quick and Easy Installation

is achieved without welding and the use of a Sequence Valve or RFHC (Radio Frequency Hydraulic Control) permits the use of a single auxillary valve to control an additional function.

Options:

- Many Fork Mounting Options

are available to match your application. Hook-on style forks, bolt-on forks, weighing forks (Weigh Forks) or Telescopic Forks are all compatible with many Fork Positioners. - Heavy Duty Load Backrests

are available for all Fork Positioners to help stabilize your load. - Various Opening Ranges

to suit most any application are available from narrow aisle, zero closing units to extra wide opening units extending far beyond the width of the truck.

- Increase Productivity

-

Carton Clamps Forklift Attachment

[woosw id="19160"]Whether you’re handling consumer paper products, appliances, consumer electronics, wine packaged foods (canned or boxed), chemicals or plastics, Atlantic Coast ToyotaLift offers a solution: Clamps durable enough for the toughest conditions, versatile and easy to service. Protect your products and speed up your workflow with just the right clamp for the job. Ask your Atlantic Coast Toyotalift representative about your specific needs.

Carton Clamps we offer:

J-Series: 1,750 pounds – 4,850 pounds

Achieve all the benefits of handling unitized loads in your manufacturing and distribution operation with Cascade’s J-Series Carton Clamps. Allowing efficient handling of a wide range of low, medium and high-density products including consumer paper products, appliances, consumer electronics, wine, packaged foods (canned or boxed), chemicals and plastics.

J-Series White Goods: 1,750 – 3,475 pounds

Designed for the warehousing, beverage, white goods, appliance and electronics industries, the WG Model clamps allow palletless handling, which improves warehouse space utilization. The WG model features and a variety of options result in improved productivity and less product damage.

J-Series Doublewide Carton Clamps: 2,500 pounds

Achieve all the benefits of handling wider loads in your manufacturing and distribution operation with Cascade’s J-Series Double Wide Carton Clamps. Allowing efficient handling of a wide range of low, medium and high density products including consumer paper products, appliances, consumer electronics, wine, packaged foods (Canned or Boxed), chemicals and plastics.

J-Series Tipping Clamps: 2,640 pounds

Designed for magnum and T loaded appliances in trailers. Articulating pads securely hold the load without damage. The sideshifting feature allows the operator to easily maneuver the product being handled.